We are a dynamic and constantly evolving company,

founded in 2015,

with significant experience in the field

of precision mechanics,

specialized

in the production of gauges and equipment.

OUR SERVICES

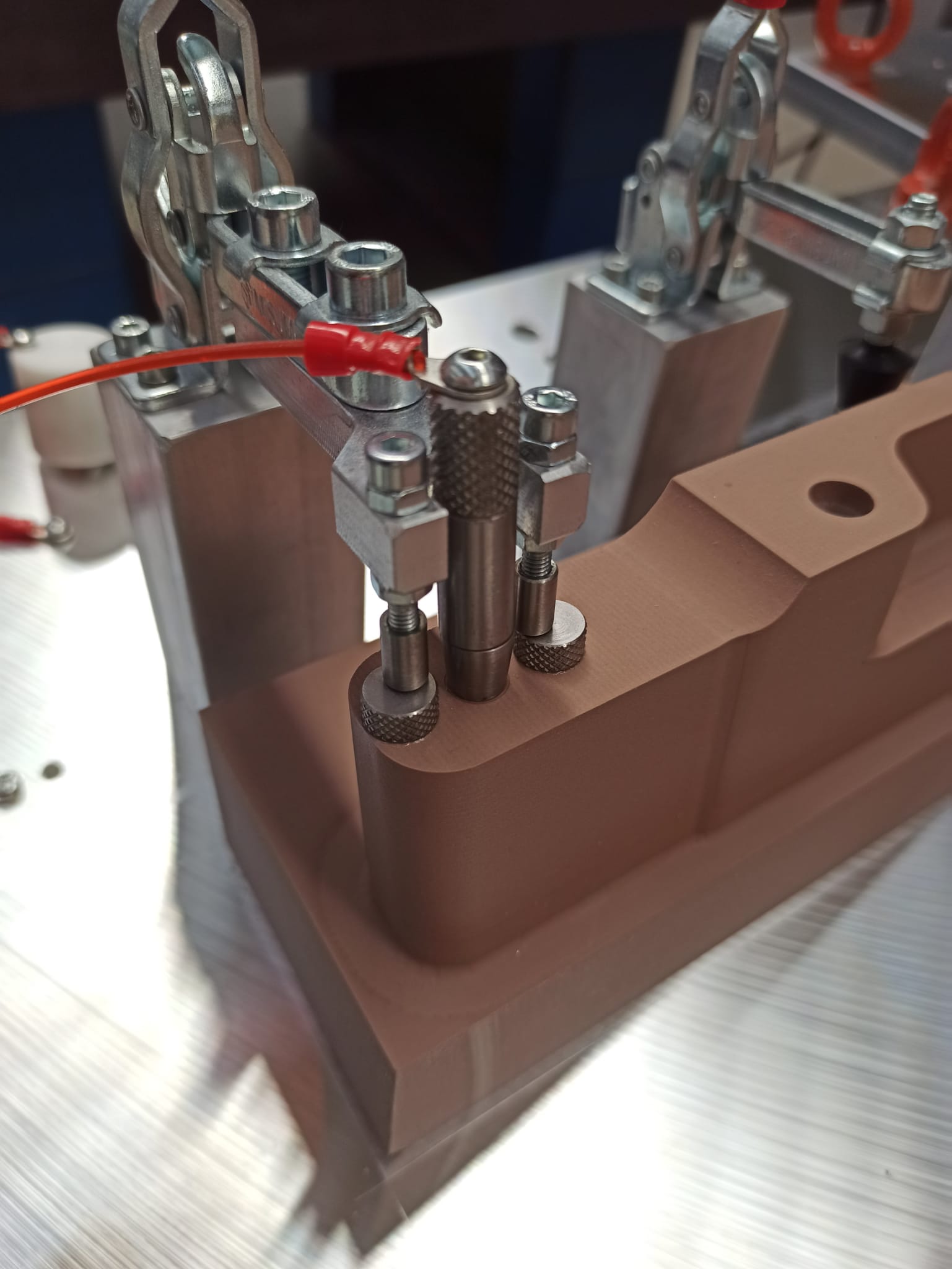

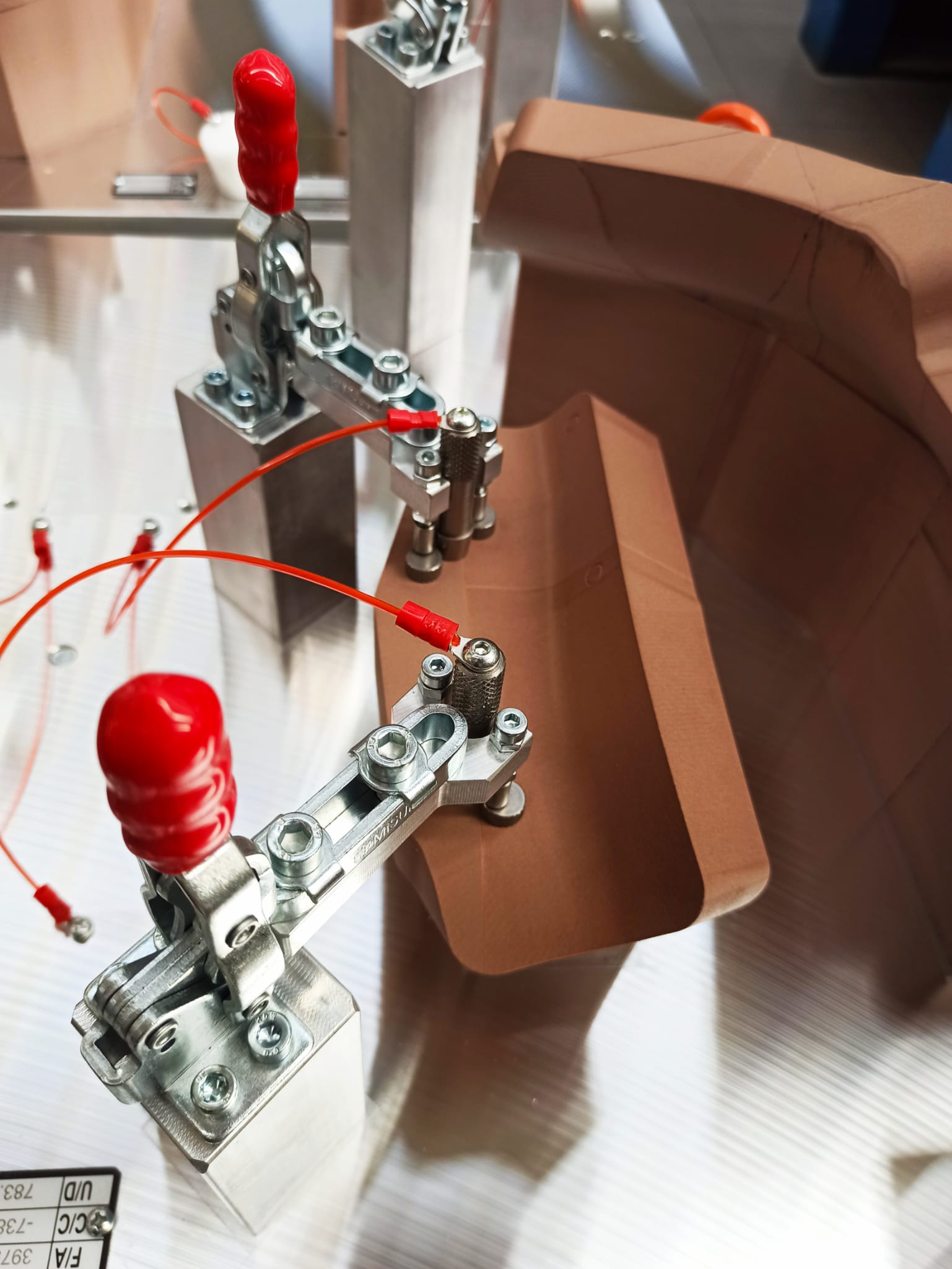

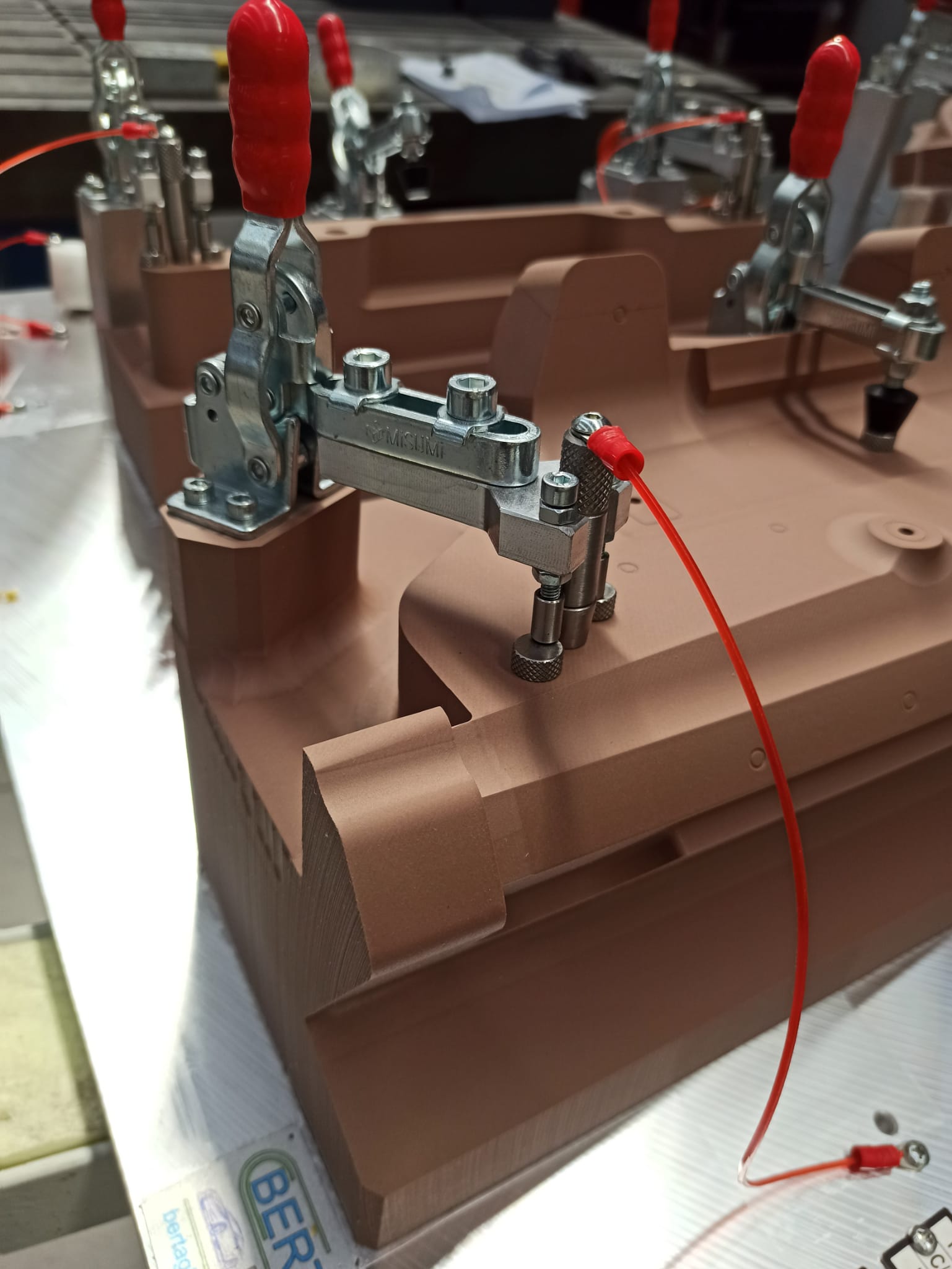

CONTROL GAUGES

Essential in our production processes to ensure compliance with dimensional requirements and product quality.

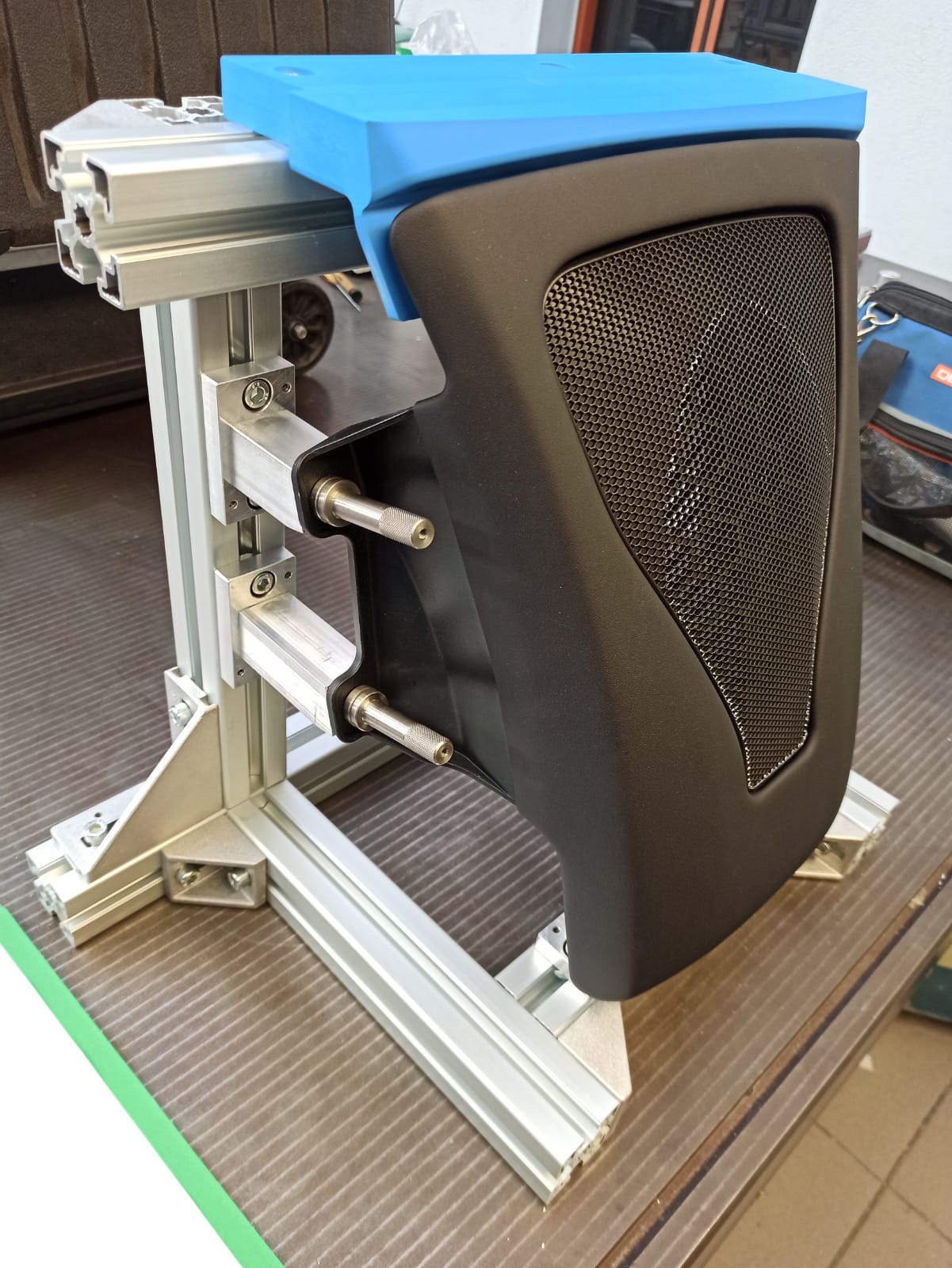

EQUIPMENT

MILLING

INNOVATION WITH SOLUTION

One of the features that has always set us apart is our ability to work as a team, a key element in our daily partnership with clients. From the initial offer stage, we anticipate their production needs, which are in constant and natural evolution.

Thanks to a lean and flexible organizational structure, to our collaboration with numerous companies in the industry, and to the solid experience of our team of designers, draftsmen, milling specialists, and testers, we guarantee expertise and reliability — the result of years of work in the technological and IT sector.

Our constant attention, sense of responsibility, and commitment to customer satisfaction guide everything we do, ensuring high-level results and tailor-made solutions.

OUR WORLD

An innovative company, specialized in the development and

implementation of design solutions; focused on maximum

customer satisfaction in both the Automotive sector and other

production and prototyping fields.

Our main goal is

to constantly seek innovative and improved solutions,

positioning ourselves as a reliable Partner for design solutions

and integrated technological and production services.

Our offering, precise and tailor-made according to the customer's specific needs, ranges from simple measurement supports for metrological rooms

to complex gauges complete with: dimensional certification, operating instructions, and post-delivery support.

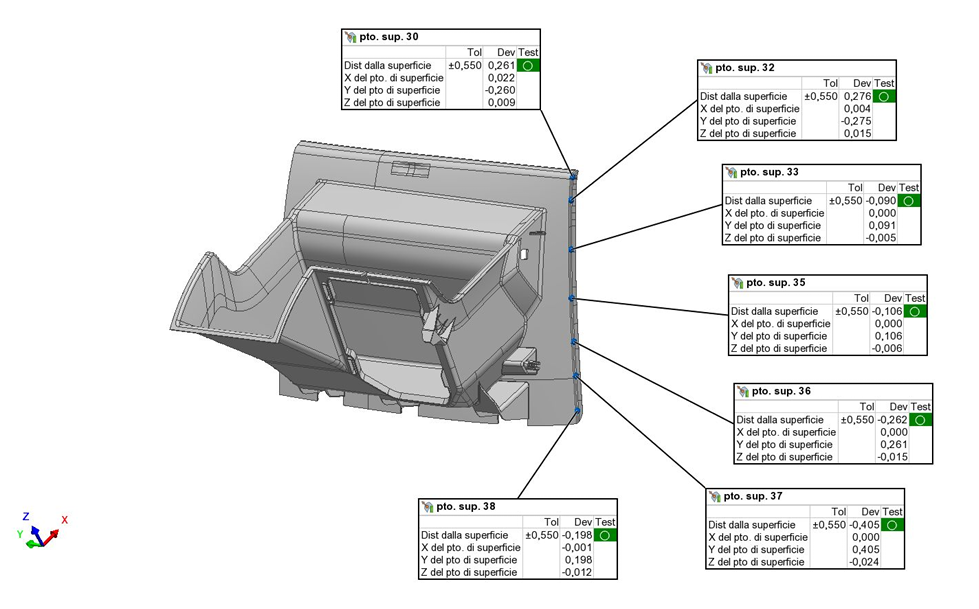

DIMENSIONAL CERTIFICATION

Metrological inspection is an essential phase of our production process.

To ensure that a component meets the required dimensional characteristics, such as height, length, and width, it must be measured using appropriate instruments. Measurement accuracy on manufactured parts is crucial in the industrial sector. A non-compliant supply in this regard can easily be contested and, in some cases, not paid for.

Dimensional measurements are therefore an essential step to ensure the product's compliance with the design, regulatory standards, customer specifications, and legal requirements.

We offer accurate dimensional inspection on manufactured products and ensure compliance with dimensional requirements through detailed reports and dimensional certification.

Performing measurements directly in the workshop allows us to keep production consistently within tolerance. Every manufactured or incoming part is certified: accurate, and ready to be delivered or assembled.

All our products are quality and quantity guaranteed through the issuance of a quality certificate, which confirms the numerous inspections carried out in our metrological room. Moreover, all equipment and instruments in the metrological room are subject to regular calibration and periodic inspections by certified authorities.

Quality Policy

The Quality Policy promoted and defined by the Management of FILOCRATE is fundamentally based on Customer System satisfaction.

To this end, FILOCRATE considers a policy based on the following elements to be essential:

- clarity during the contractual phase and full compliance with the agreed contractual specifications;

- the continuous improvement of its System and consequently of the quality standards of the service offered;

- compliance with industry regulations and laws;

- the provision of services that meet the needs of the Customer System;

- the employment of professionally qualified human resources oriented towards a culture of quality.

The Quality Policy is subject to annual Review by the Management.

During the Review, the Management assesses the full or partial achievement of the established objectives and defines the goals to be pursued in the following year.

The milling department is equipped with a state-of-the-art machine fleet, featuring 3- and 5-axis machining centers, allowing us to ensure hundredth-millimeter tolerances. Thanks to our highly skilled and detail-oriented staff, we can perform complex machining with reduced lead times, thus increasing both production volume and component quality.

Reliability and precision, from design to finished product.

We are always ready to answer your questions!

Contact us for information or to receive a personalized quote. We are here to offer you tailored solutions!

Via Marconi, 8, 10044 Pianezza TO

Tel. 011 1950 9243

bertaglia@bertagliamodelli.com

P.IVA 11396970011